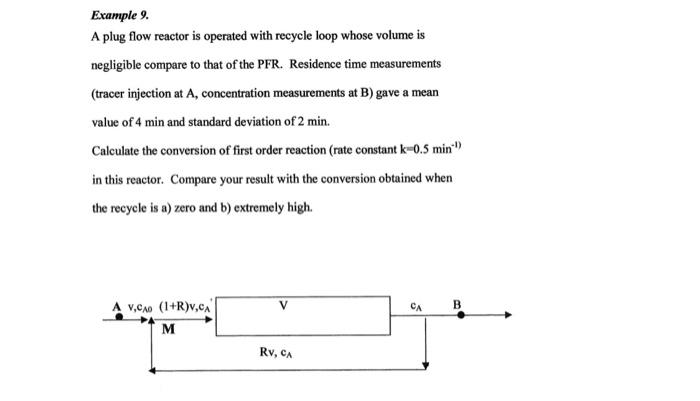

In the previous paragraph we derived our plug flow reactor model: In this example, we will demonstrate how bayesian optimization can locate the optimal conditions for a plug flow reactor (pfr) and produce the maximum yield.

Plug Flow Reactor Continuous Stirred Tank Reactor And Actual Reactor Download Scientific Diagram

C a= f a v ii.

Plug flow reactor example. The analytical form of the objective. Complete radial mixing and no axial mixing in the elemental volume. C a= c a0 (1 x) idealgas(variableflowrate) a.

The reactor itself may consist of an empty Isothermal plug flow reactor a c b z=0 z=3 the components a and c react to form component b. This example considers the thermal cracking of acetone, which is a key step in the production of acetic anhydride.

(9) (strictly speaking this formulation of the model is only useful for reactions in liquid phase where the reactants are in a solvent because only then can velocity u be assumed constant. Fluid going through a pfr may be modeled as flowing through the reactor as a series of infinitely thin. V = v 0 andc a= c a0 (1 x) 12

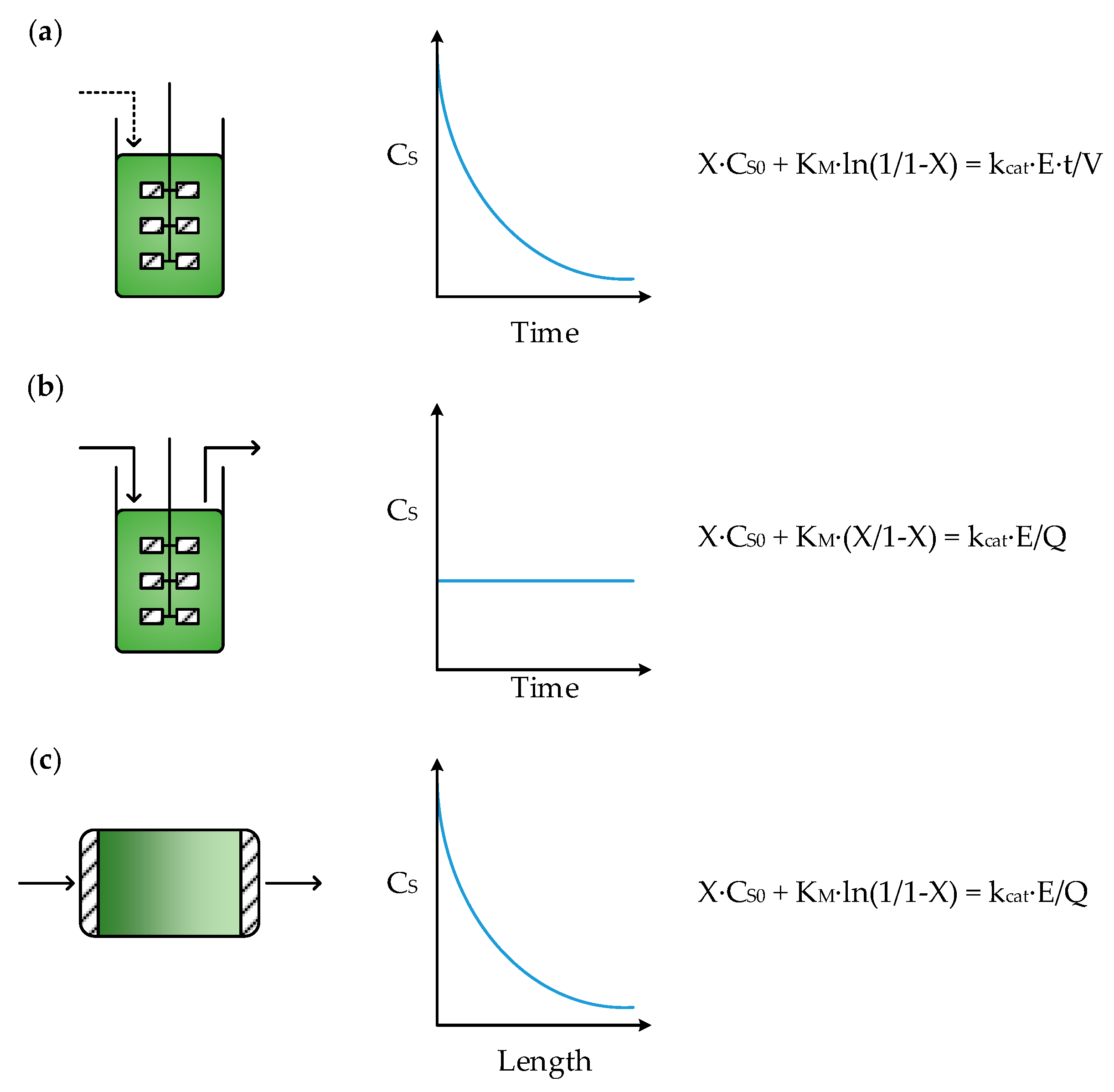

A shower curtain, the walls of a bathtub, or a canyon wall seep all exhibit the properties of an open plug flow reactor. Isothermal plug flow reactor model. Plug flow reactors (pfrs) another type of reactor used in industrial processes is the plug flow reactor (pfr).

Debasree ghosh, lecture notes on polymer reaction engineering, module ii: In pfrs, however, the reactor contents are not continuously stirred. A number of discrete plug flow reactors of an annular shape have been considered to represent the reactor.

Plug flow reactor are used to carry out the reactions like suzuki reaction, hoffmann reaction, grignard reaction, oxidation reaction, biocatalysis and many more. The mole balance for each component is given by the following differential equations a 2 2 a dc uk dz =− c (1) Consider a simple rectangular reactor which has a gas inlet on one side, an exhaust on the other, and deposition on the top and bottom walls (and the sample, resting on the bottom surface):

C a= c a0 (1 x) (1 + x) p p 0 t 0 t liquidorgas(constantvolume) a. Pfrs carry out power law reactions faster than cstrs and generally require less volume. Instead, chemical species are flowed along a tube as a plug, as shown in figure 25.2.

Perpendicular to the flow direction, the gas is considered to be completely homogeneous. The plug flow reactor model is a model used to describe chemical reactions in continuous, flowing systems of cylindrical geometry. Let’s look at gas phase reactions a bit later.)

No mixing between the adjacent annular pfr's. A plug flow reactor (pfr) is a tubular reactor used in chemical reactions. The assumptions used in the development of model are:

To study this reactor we first need to define some notation for the dimensions and coordinates. Introduction accessing aspen plus ™ Reactants enter one end of the pfr, while products exit from the other end of the tube.

A plug flow reactor (pfr) is a type of chemical reactor where the influent is pumped into the pipe. The pfr model is used to predict the behavior of chemical reactors of such design, so that key reactor variables, such as the dimensions of the reactor, can be estimated. Plug flow reactors are unique in the sense that operation in parallel or series give the same conversion if the space time is held constant.

A pfr is useful because of high volumetric conversion and good heat transfer. Reactor volume and flow path length, l, such that x l < 10 3 cells/100 ml 2. Given that the system is gas phase and isothermal, determine the reactor volume when x = 0.8 x e.

For example, a pfr reactor liquid volume of 1.41 m 3 is required to achieved 40% c4h10 conversion while a cstr reactor requires only liquid volume of 1.30 m 3. Plug flow is an extremely simple tool, but we're going to put it to use anyway. Typically an ideal gas flows through it at a constant mass flow rate \(\dot{m}\).

F a= f a0 (1 x) liquid(constantflowrate) a. The degree of mixing and residence time in reactors affect the degree of completion of reactions within the reactor. C a= n a v andn a= n a0 (1 x) idealgas(variablevolume) a.

V = v 0 (1 + x) p 0 p t t 0 b. Solving ode’s in matlab isothermal plug flow reactor a plug flow reactor is operated as shown in figure 1 below. Determine x e for a pfr with no pressure drop, p = p 0.

Chlorine concentration which must be added to insure that there is detectable chlorine at pfr exit (detection level = c l = 0.05 mg/l) 1. C a= c a0 (1 x) (1 + x) p p 0 t 0 t (b) batch i. V= v 0 (1 + x) p 0 p t t 0 b.

Another sort of plug flow reactor could be described as “open”. Like the cstrs, a constant flow of reactants and products and exit the reactor. Reactors include lakes, rivers, and sedimentation tanks.

Examples For Design Concepts Of Fixed-bed Reactors A Axial-flow Download Scientific Diagram

Completely Mixed Flow Reactorcmfr And Plug Flow Reactorpfrcmfr Vs Pfr - Youtube

Thoughts On Problem Solving Pfrcstr Example

Apfr Introduction

Plug Flow Reactor Example

Catalysts Free Full-text Reactor Selection For Effective Continuous Biocatalytic Production Of Pharmaceuticals Html

Chemical Reactor Selection And Design Rajesh Kumar Bhagat

Plug Flow Reactor Pfr Sizing And Conversion Example - Youtube

Plug Flow Reactor Overview - Youtube

Solved Example 9 A Plug Flow Reactor Is Operated With Cheggcom

Variable Density Reaction In A Pfr - Youtube

Plug Flow Reactor - An Overview Sciencedirect Topics

Isothermal Plug Flow Reactor Part 1 - Youtube

Transient Dynamics In A Plug Flow Reactor Pfr Download Scientific Diagram

Homesnanoaaudk

L 2 1 Review What Size Reactors To

Visual Encyclopedia Of Chemical Engineering

Background - Continuous Reactor Hydrodynamics

Matlab In Chemical Engineering At Cmu