(25.1) a k b + c. Given that the system is gas phase and isothermal, determine the reactor volume when x = 0.8 x e.

Thoughts On Problem Solving Pfrcstr Example

Determine x e for a pfr with no pressure drop, p = p 0.

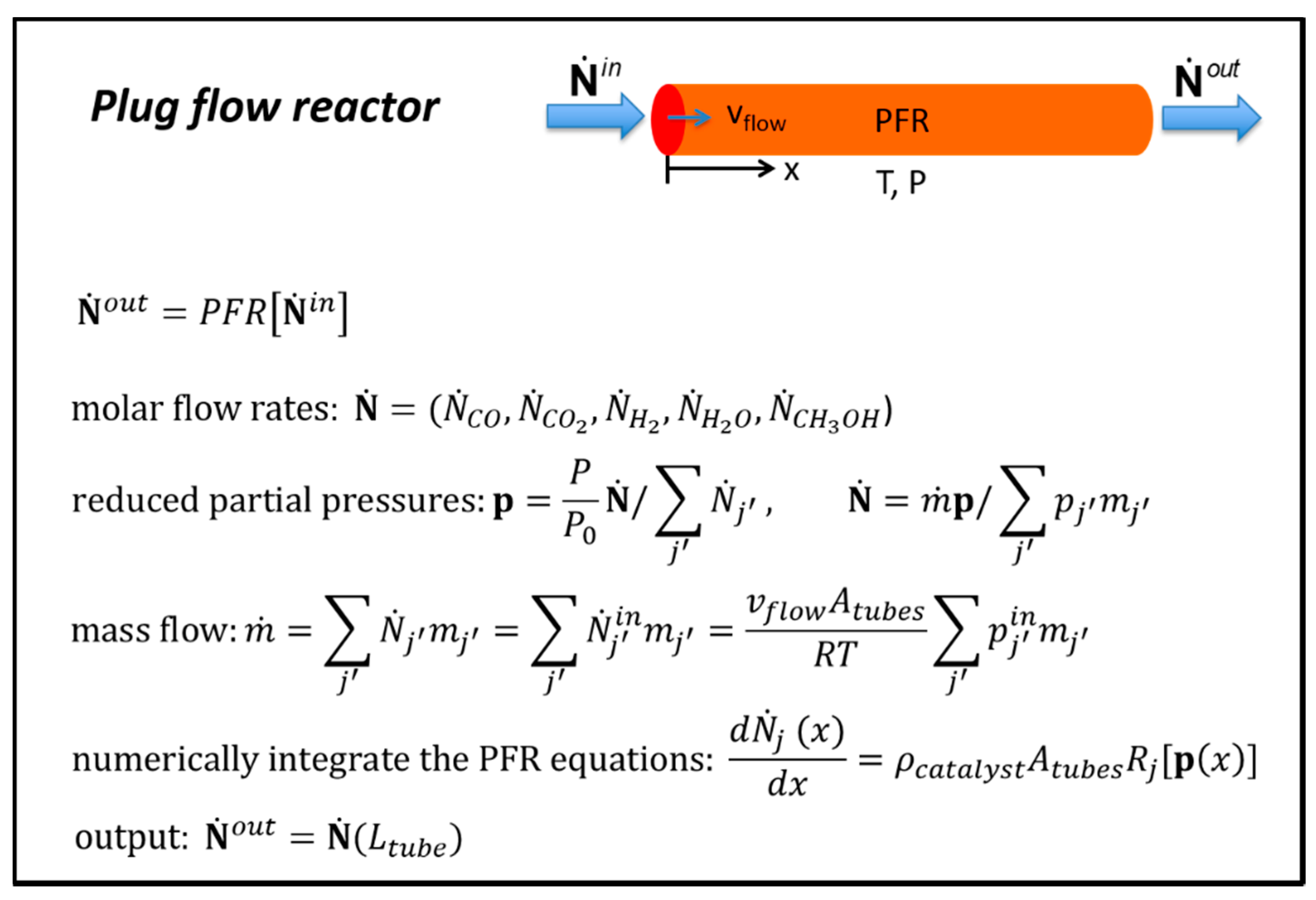

Plug flow reactor example problem. F a= f a0 (1 x) liquid(constantflowrate) a. This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in hysys (as shown in the picture above). The phrase “plug flow profile” indicates that there is uniform velocity with no radial variation (but.

A number of discrete plug flow reactors of an annular shape have been considered to represent the reactor. The system may be either contained (as in a water main, oil pipeline, or blood vessel) or open (as in a shower curtain, stream, or canyon. C a= f a v ii.

The same example problem has been worked in aspenand matlab. Given their low friability, most of the biomass feedstocks. In a plug flow reactor, nutrients (and sometimes organisms) are introduced to the reactor continuously and move through the reactor as a “plug”.

import cantera as ct import numpy as np ##### # input parameters ##### t_0 = 1500.0 # inlet. This example illustrates the process of modeling a pfr reactor in which one or more compounds are recycled, as shown in the following figure. To solve this problem, the reactor can be initialized with a high temperature and/or radical concentration.

Example problem 1 develop equations to determine plug flow reactor size for 50% conversion of reactant a. The assumptions used in the development of model are: Water is run through the reactor at a flow rate q(m 3/sec ) and t=0 the reactant a is added to the input stream on a continuous basis.

Problem 5.10 (p.114) in a plug flow reactor a gaseous feed of pure (2 mol / l, 100 mol / min) decomposes to give a variety of products. The rates of reaction are also evaluated, and the function returns the numerical value of the right hand side. Complete radial mixing and no axial mixing in the elemental volume.

Here, the fresh inlet is mixed with the recycle stream ; Debasree ghosh, lecture notes on polymer reaction engineering, module ii: Optimization of plug flow reactor by varying temperature and pressure.

Nonisothermal operation of ideal reactors plug flow reactor t o f jo, q o t f j t m,q mt t o t m mo assumptions: Steady state two types of problems: You can download the aspen backup file here that completes this problem.

% myode1.m % isothermal plug flow reactor % this function provides the function f(z,y) to be integrated % 15.9) are not usually applied to biomass gasification because of their remarkable limitations when processing this feedstock. A problem can be the ignition of a cstr:

Reactor volume and flow path length, l, such that x l < 10 3 cells/100 ml 2. Pure a is fed into the cstr at a volumetric flow rate of 10 m 3 / s and a temperature, t 0. No mixing between the adjacent annular pfr's.

Given desired production rate, conversion and kinetics and other parameters, determine the required reactor size, heat duty and temperature profile. An example for this procedure is the combustor example. Calculate the size of the plug flow reactor, operating at 100°c and 1

For batch reactors, conversion is a function of time whereas for flow reactors at steady state it is a. The third general type of reactor is the plug flow reactor (pfr). It can be shown2 that the absence of axial mixing allows the achievable reactant conversion to be maximized.

The residence time in the entrained flow reactor is very short and consequently the fuel particles need to be finely ground (<75 μm) for the reactions to proceed completely. The resulting stream enters the pfr reactor and stream is the reactor effluent. Sean powers on 16 apr 2019.

Follow 202 views (last 30 days) show older comments. If the reactants are not reactive enough, the simulation can result in the trivial solution that inflow and outflow states are identical. Chlorine concentration which must be added to insure that there is detectable chlorine at pfr exit (detection level = c l = 0.05 mg/l) 1.

But unfortunately i did not and i don't have the time or skillset. Solving ode’s in matlab the distance from the inlet (z) is the independent variable. The stoichiometry of the reaction is 2a → r + s.

The simulation of a lagrangian fluid particle, and the simulation of a chain of reactors. The reactor itself may consist of an empty

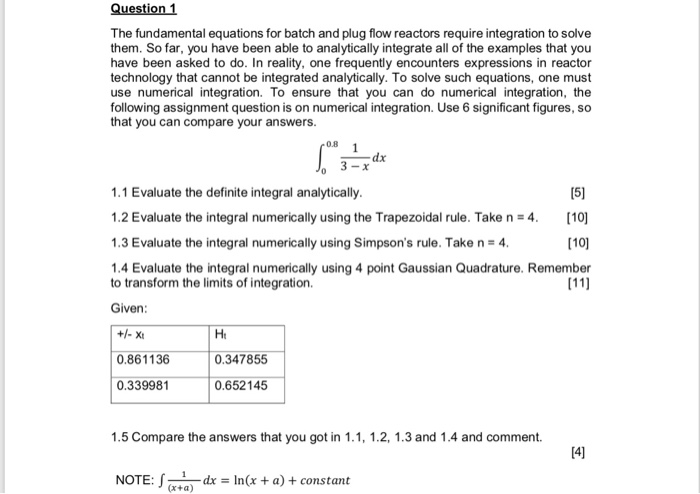

Solved Question 1 The Fundamental Equations For Batch And Cheggcom

Reactor-separator Configurations Under Consideration A Semibatch Download Scientific Diagram

Mass And Energy Balances

Plug Flow Reactor Example

Isothermal Plug Flow Reactor Part 1 - Youtube

Elements Of Chemical Reaction Engineering

Simulation Of Plug Flow Reactor Pfr In Aspen Hysys - Lecture 64 - Youtube

Chemengineering Free Full-text Understanding Catalysisa Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

A Front View Of The Plug Flow Reactor And B Surface Area Dimensions Download Scientific Diagram

Plug Flow Reactor Pfr Sizing And Conversion Example - Youtube

Matlab In Chemical Engineering At Cmu

L 2 1 Review What Size Reactors To

One-dimensional Pseudo-homogeneous Plug Flow Reactor Model Download Scientific Diagram

Introduction To Energy Balances For Plug Flow Reactors - Youtube

Plug Flow Reactor Overview - Youtube

Plug Flow Reactor Continuous Stirred Tank Reactor And Actual Reactor Download Scientific Diagram

Introduction To Energy Balances For Plug Flow Reactors - Youtube

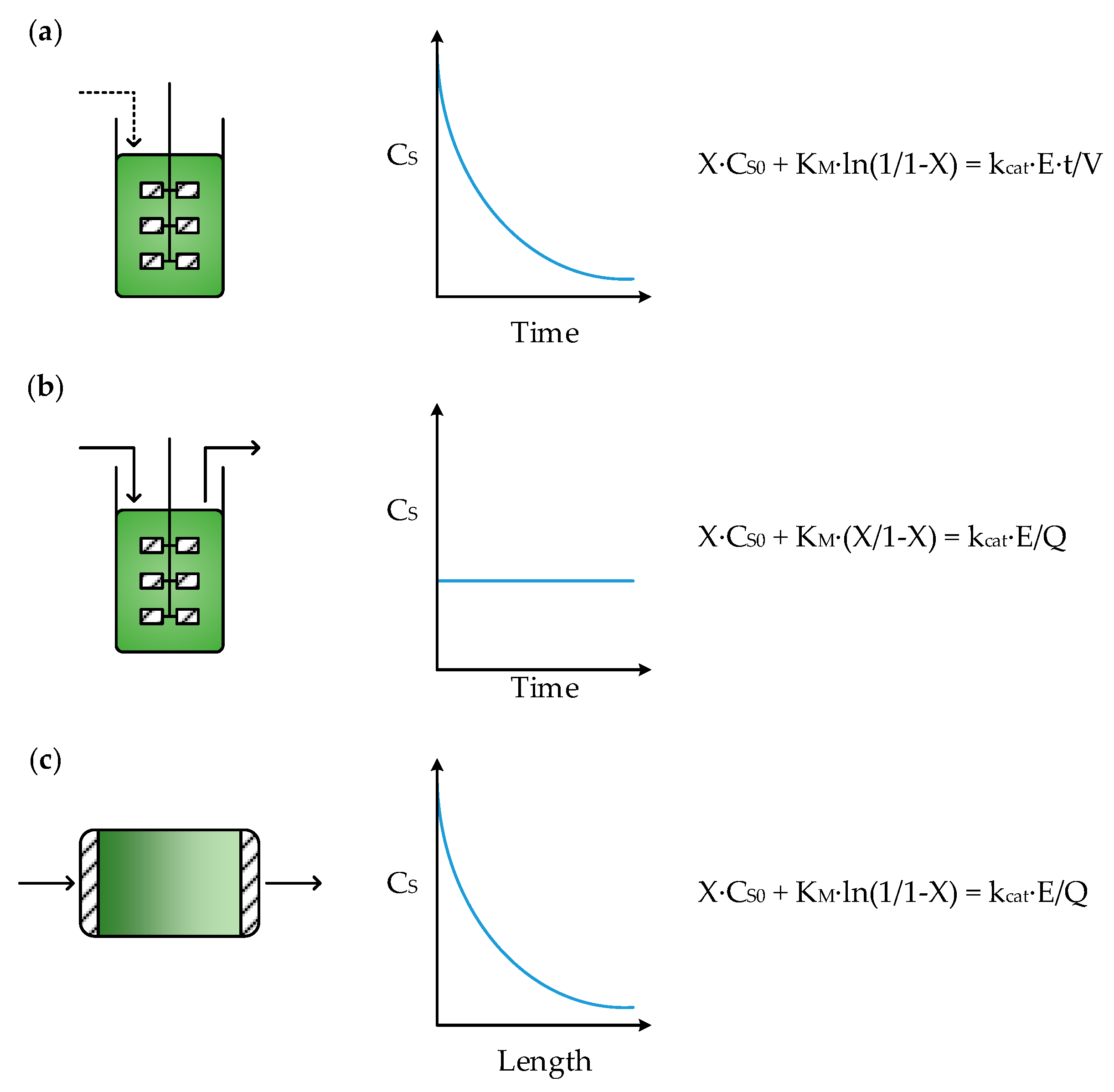

Catalysts Free Full-text Reactor Selection For Effective Continuous Biocatalytic Production Of Pharmaceuticals Html

Chemical Reactor Selection And Design Rajesh Kumar Bhagat